| Availability: | |

|---|---|

| Quantity: | |

Designed exclusively for beginners and small businesses, the Easy to Operate 3W 5W 10W UV Marker features a one-button start system and 7-inch capacitive touchscreen (supports multi-touch and glove operation). Its plug-and-play software (compatible with Windows 10/11 and macOS) supports 12 file formats (PLT, DXF, AI, PNG, etc.) with automatic parameter optimization—simply select the material type (e.g., "aluminum," "ABS plastic"), and the machine adjusts speed/power. The 3W entry model (weight: 8kg) is perfect for startups (e.g., small jewelry studios), while the 10W version (15kg) serves light industrial needs (e.g., electronic component marking).

SINO galvanometer

355 nm Lens

BJ JCZ Control Card

JPT laser source

CRS laser source

chiller unit

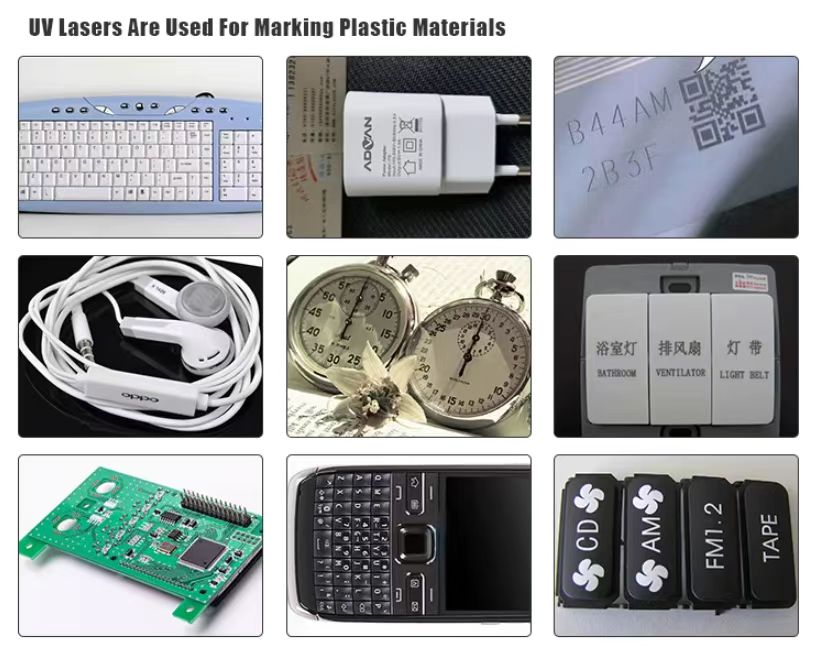

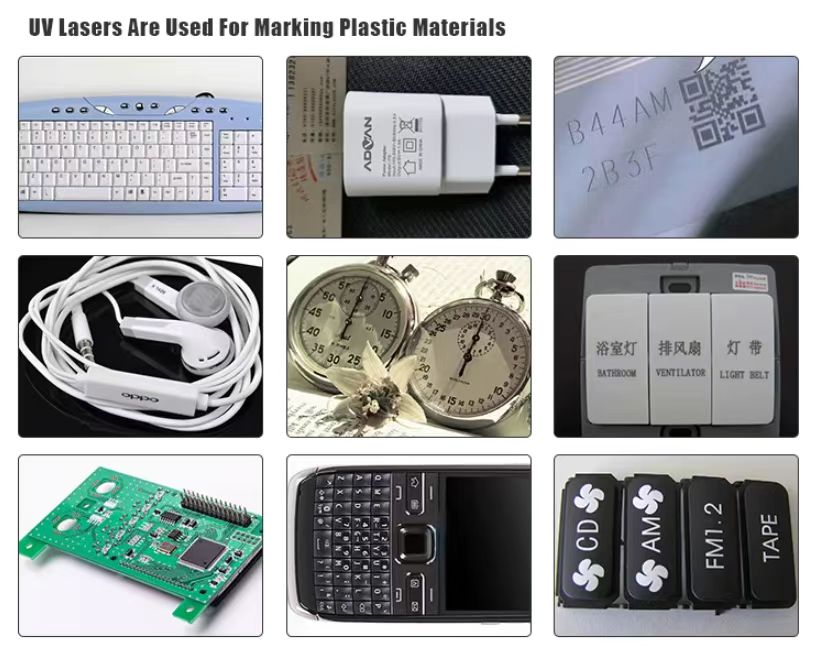

Small business adoption of UV laser markers increased 41% in 2024, driven by simplified operation (reducing training costs by 60%) and lower upfront investment (30% less than industrial-grade models). A survey of new users found 79% prioritize "ease of use" over maximum power—with 68% reporting they were able to start marking within 30 minutes of unboxing. Key growth sectors include 3D printing (marking plastic/metal prints), custom gifts (engraving personalized jewelry), and small-batch electronics (labeling circuit boards).

Guided Setup: Step-by-step on-screen instructions (with videos) reduce training time to 15 minutes—covering everything from software installation to first mark creation.

Smart Material Detection: Built-in infrared sensor automatically identifies metal/plastic substrates, adjusting laser parameters (power: 10-100%, speed: 100-5000mm/s) to avoid material damage.

Remote Support: Built-in WiFi enables real-time technical support (via screen sharing) and automatic software updates—no need to connect to a computer for maintenance.

Quiet Operation: ≤55dB noise level (equivalent to a home office printer) suitable for office environments or small workshops; no loud cooling fans.

Meets FCC regulations for electromagnetic compatibility (FCC ID: 2AXY9-UVMARKER) and CE safety standards. All power variants maintain ±0.005mm accuracy—exceeding industry entry-level standards (±0.01mm). The laser source has a 5-year warranty, and the machine passes 1000-cycle vibration testing (simulating shipping and workshop movement) with no performance issues.

Training video library tailored to specific industries: 3D printing (marking post-processing), jewelry (personalized engravings), electronics (batch numbering).

Simplified software interface with custom shortcut buttons (e.g., "Engrave Ring," "Mark PCB") for one-click operation of common tasks.

Starter kit with sample materials (aluminum sheets, plastic blocks, leather pieces), pre-designed templates (birthstones, logos), and cleaning supplies.

Compact workstation integration (optional tabletop stand with storage drawer) for small workshop spaces.

Designed exclusively for beginners and small businesses, the Easy to Operate 3W 5W 10W UV Marker features a one-button start system and 7-inch capacitive touchscreen (supports multi-touch and glove operation). Its plug-and-play software (compatible with Windows 10/11 and macOS) supports 12 file formats (PLT, DXF, AI, PNG, etc.) with automatic parameter optimization—simply select the material type (e.g., "aluminum," "ABS plastic"), and the machine adjusts speed/power. The 3W entry model (weight: 8kg) is perfect for startups (e.g., small jewelry studios), while the 10W version (15kg) serves light industrial needs (e.g., electronic component marking).

SINO galvanometer

355 nm Lens

BJ JCZ Control Card

JPT laser source

CRS laser source

chiller unit

Small business adoption of UV laser markers increased 41% in 2024, driven by simplified operation (reducing training costs by 60%) and lower upfront investment (30% less than industrial-grade models). A survey of new users found 79% prioritize "ease of use" over maximum power—with 68% reporting they were able to start marking within 30 minutes of unboxing. Key growth sectors include 3D printing (marking plastic/metal prints), custom gifts (engraving personalized jewelry), and small-batch electronics (labeling circuit boards).

Guided Setup: Step-by-step on-screen instructions (with videos) reduce training time to 15 minutes—covering everything from software installation to first mark creation.

Smart Material Detection: Built-in infrared sensor automatically identifies metal/plastic substrates, adjusting laser parameters (power: 10-100%, speed: 100-5000mm/s) to avoid material damage.

Remote Support: Built-in WiFi enables real-time technical support (via screen sharing) and automatic software updates—no need to connect to a computer for maintenance.

Quiet Operation: ≤55dB noise level (equivalent to a home office printer) suitable for office environments or small workshops; no loud cooling fans.

Meets FCC regulations for electromagnetic compatibility (FCC ID: 2AXY9-UVMARKER) and CE safety standards. All power variants maintain ±0.005mm accuracy—exceeding industry entry-level standards (±0.01mm). The laser source has a 5-year warranty, and the machine passes 1000-cycle vibration testing (simulating shipping and workshop movement) with no performance issues.

Training video library tailored to specific industries: 3D printing (marking post-processing), jewelry (personalized engravings), electronics (batch numbering).

Simplified software interface with custom shortcut buttons (e.g., "Engrave Ring," "Mark PCB") for one-click operation of common tasks.

Starter kit with sample materials (aluminum sheets, plastic blocks, leather pieces), pre-designed templates (birthstones, logos), and cleaning supplies.

Compact workstation integration (optional tabletop stand with storage drawer) for small workshop spaces.

Q: Do I need design experience to use it?

A: No—pre-loaded templates (100+ options) and drag-and-drop editing (add text, shapes, or images) make it beginner-friendly. You can also import photos and convert them to engraving patterns with one click.

Q: Can it handle batch production?

A: Yes, the software supports sequential numbering (auto-increment from 001 to 999) and batch processing of up to 10,000 items—with a preview function to check all marks before starting.

Q: What’s the maximum size of material it can mark?

A: The standard working area is 100×100mm, but an optional extension kit expands it to 200×200mm—suitable for larger items like tablet cases or small wooden plaques.

Q: Do I need design experience to use it?

A: No—pre-loaded templates (100+ options) and drag-and-drop editing (add text, shapes, or images) make it beginner-friendly. You can also import photos and convert them to engraving patterns with one click.

Q: Can it handle batch production?

A: Yes, the software supports sequential numbering (auto-increment from 001 to 999) and batch processing of up to 10,000 items—with a preview function to check all marks before starting.

Q: What’s the maximum size of material it can mark?

A: The standard working area is 100×100mm, but an optional extension kit expands it to 200×200mm—suitable for larger items like tablet cases or small wooden plaques.

content is empty!