| Availability: | |

|---|---|

| Quantity: | |

JW-W1000

JW

Multi-Functional 3 in 1 Handheld Laser Welder for Stainless Steel Workshops

1.Non-contact cleaning, easy to operate, high efficiency,and long service life;

2.With universal wheels, it is easy to move and suitable for various site needs;

3.The parameters of the human-machine operation inteerface are adjustable,

intuitive and simple, and easy to adjust.

1. Built-in touch screen control system 2. Laser source (Inside) 3. Handheld laser gun 4. Automatic wire feeder 5. Intergrated chiller (Inside) 6. Protective glasses 7. Welding Gun Nozzle 8. Wire Guiding Tube 9. Control Cable 10. Serial Line 11. Wire feed wheel 12. Wrench 13. Welding Head holder |

|

Laser Source

Brand: Raycus/MAX/JPT/KPL (Optional)

Power: 1000W/1500W/2000W/3000W

Continuous fiber laser adopts modulardesign. Highly integrated system, mainte-nance-free, and high reliability. The laserpower is continuously adjustable,

withhigh beam quality and high laser stabili-ty. It is an ideal laser source for laser finecutting, precision welding and other.

Laser Welding Head

Brand: WSX/Qilin as optional

Handheld Laser Processing Head-Cut/Weld/ Clean 3-in-one laser controlsystem.

Multiple safety protection with auto beamoff function once the nozzle goes awayfrom workpiece. Various tip assembliesin standard kit to fulfill cutting,

welding and cleaning.Wide welding seam, low porosity and ex-cellent melting pool protection.

Control Panel

Touch screen makes you change the pa-rameters quickly when wearing gloves.Multiple sets of parameters can be saved,and there is no need to adjust again

formultiple welding in the future after onetest.

It can support Chinese, English,Spanish,German, Korean, Vietnamese, Russian,Japanese language interface.Customize according to customer's re-quirements.

Water Chiller

Adopted water chiller system, the virtu-ous cycle system to better guarantee theoperation of the machine.

When using an industrial chiller,purewater is used in summer, and antifreezeis used when the room temperature isbelow 5 degrees Celsius in winter.

Switchback to pure water when the temperaturewarms up.

Wire Feeder

Standard automatic wire feeding systemand dual motors.

The forward and reverse and the speedof wire feeding can be adjusted throughthe control panel.

Product Parameter | |

Laser source | Raycus/MAX/JPT/KPL (Optional) |

Laser power | 1000w/1500w/2000w/3000w |

Laser head | WSX/Qilin as optional |

Funcition | Welding, cutting, cleaning |

Welding thickness | 0-5mm(Depends on the material and power) |

Cooling method | Water cooling |

Position method | Red light positioning |

Laser wavelength | 1064nm |

Application material | Metal Stainless Steel Aluminum |

Power supply | AC220V /380V+/-10% ; 50Hz (or 60Hz) |

Protective gas | Argon and nitrogen |

Welding form | Continuous |

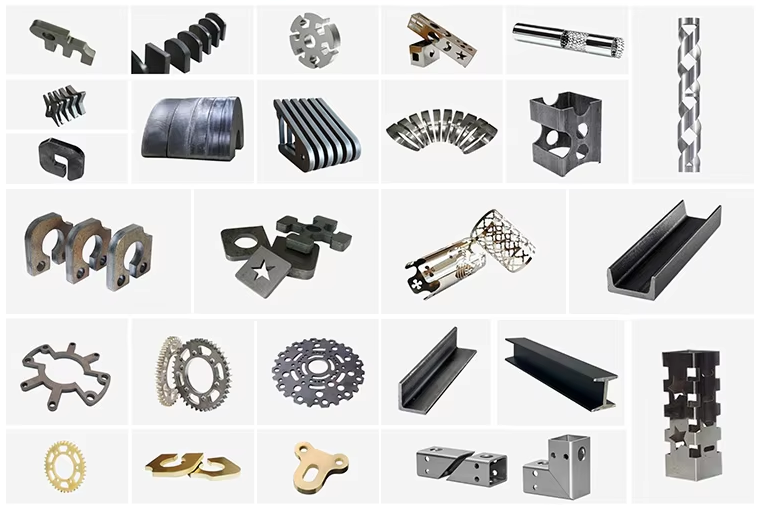

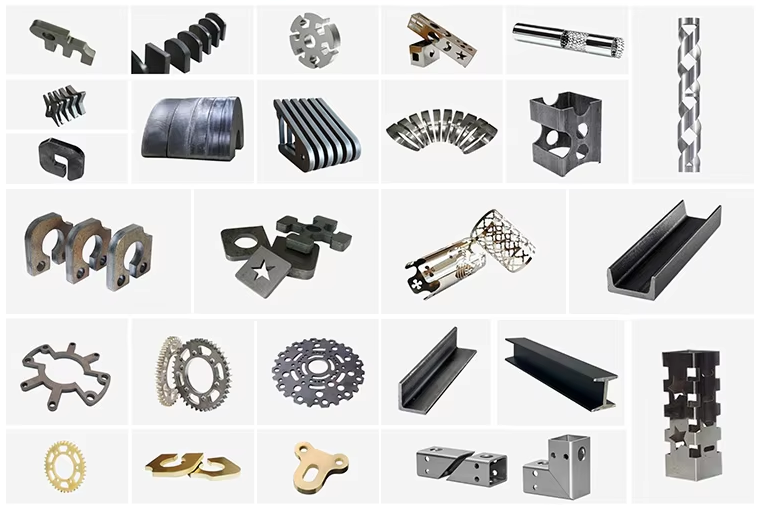

APPLICATION FEILD

Laser welding machines have a wide range of applications. Their core fields include automotive manufacturing (welding of car bodies, batteries, and power components to meet lightweight requirements), electronics and microelectronics (chip packaging, precision welding of consumer electronics with micrometer-level accuracy), aerospace (welding of hard-to-weld materials such as titanium alloys to ensure high reliability), medical devices

(aseptic welding of implantable devices and diagnostic equipment, in line with biocompatibility), as well as hardware molds (welding of structural parts and mold repair), and fields such as photovoltaics and shipbuilding, adapting to the needs of special materials, high precision, high reliability, etc.

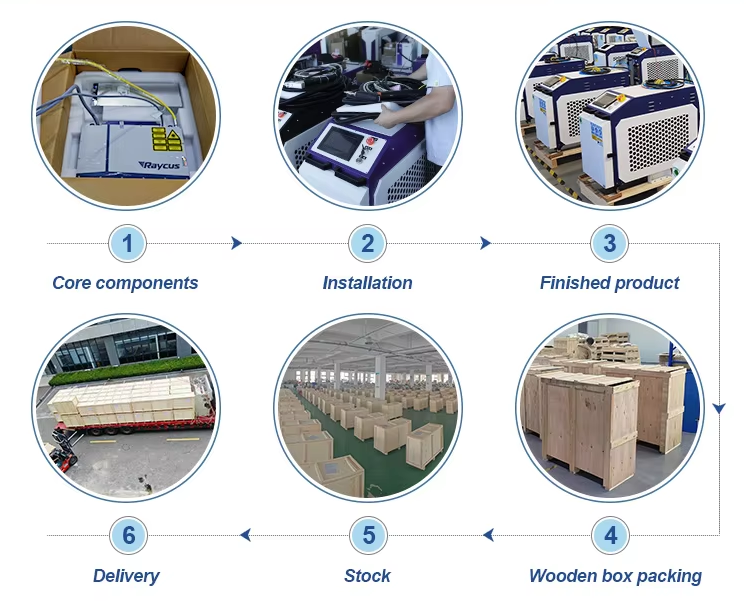

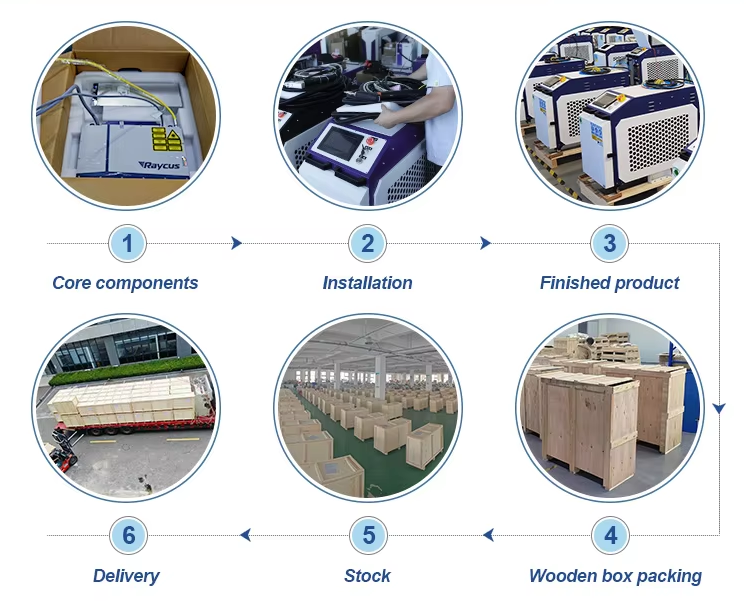

PAYMENT AND SHIPPING

1.The delivery lead time would be 2-7 working days after receiving the payment.

2.As for the wholesalers/distributors, we could send the cargo by air, by sea or by railways via reliable forward.

3. Payment: T/T, Paypal, Alipay

4. Currency of payment: USD / RMB

Packaging details | Standard export packing, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety; |

Shipping methods | 1.Shipping by sea(recommend big product or a lot of goods of the order) |

2.By air | |

3.By express: EMS, DHL, Fedex, UPS etc |

Multi-Functional 3 in 1 Handheld Laser Welder for Stainless Steel Workshops

1.Non-contact cleaning, easy to operate, high efficiency,and long service life;

2.With universal wheels, it is easy to move and suitable for various site needs;

3.The parameters of the human-machine operation inteerface are adjustable,

intuitive and simple, and easy to adjust.

1. Built-in touch screen control system 2. Laser source (Inside) 3. Handheld laser gun 4. Automatic wire feeder 5. Intergrated chiller (Inside) 6. Protective glasses 7. Welding Gun Nozzle 8. Wire Guiding Tube 9. Control Cable 10. Serial Line 11. Wire feed wheel 12. Wrench 13. Welding Head holder |

|

Laser Source

Brand: Raycus/MAX/JPT/KPL (Optional)

Power: 1000W/1500W/2000W/3000W

Continuous fiber laser adopts modulardesign. Highly integrated system, mainte-nance-free, and high reliability. The laserpower is continuously adjustable,

withhigh beam quality and high laser stabili-ty. It is an ideal laser source for laser finecutting, precision welding and other.

Laser Welding Head

Brand: WSX/Qilin as optional

Handheld Laser Processing Head-Cut/Weld/ Clean 3-in-one laser controlsystem.

Multiple safety protection with auto beamoff function once the nozzle goes awayfrom workpiece. Various tip assembliesin standard kit to fulfill cutting,

welding and cleaning.Wide welding seam, low porosity and ex-cellent melting pool protection.

Control Panel

Touch screen makes you change the pa-rameters quickly when wearing gloves.Multiple sets of parameters can be saved,and there is no need to adjust again

formultiple welding in the future after onetest.

It can support Chinese, English,Spanish,German, Korean, Vietnamese, Russian,Japanese language interface.Customize according to customer's re-quirements.

Water Chiller

Adopted water chiller system, the virtu-ous cycle system to better guarantee theoperation of the machine.

When using an industrial chiller,purewater is used in summer, and antifreezeis used when the room temperature isbelow 5 degrees Celsius in winter.

Switchback to pure water when the temperaturewarms up.

Wire Feeder

Standard automatic wire feeding systemand dual motors.

The forward and reverse and the speedof wire feeding can be adjusted throughthe control panel.

Product Parameter | |

Laser source | Raycus/MAX/JPT/KPL (Optional) |

Laser power | 1000w/1500w/2000w/3000w |

Laser head | WSX/Qilin as optional |

Funcition | Welding, cutting, cleaning |

Welding thickness | 0-5mm(Depends on the material and power) |

Cooling method | Water cooling |

Position method | Red light positioning |

Laser wavelength | 1064nm |

Application material | Metal Stainless Steel Aluminum |

Power supply | AC220V /380V+/-10% ; 50Hz (or 60Hz) |

Protective gas | Argon and nitrogen |

Welding form | Continuous |

APPLICATION FEILD

Laser welding machines have a wide range of applications. Their core fields include automotive manufacturing (welding of car bodies, batteries, and power components to meet lightweight requirements), electronics and microelectronics (chip packaging, precision welding of consumer electronics with micrometer-level accuracy), aerospace (welding of hard-to-weld materials such as titanium alloys to ensure high reliability), medical devices

(aseptic welding of implantable devices and diagnostic equipment, in line with biocompatibility), as well as hardware molds (welding of structural parts and mold repair), and fields such as photovoltaics and shipbuilding, adapting to the needs of special materials, high precision, high reliability, etc.

PAYMENT AND SHIPPING

1.The delivery lead time would be 2-7 working days after receiving the payment.

2.As for the wholesalers/distributors, we could send the cargo by air, by sea or by railways via reliable forward.

3. Payment: T/T, Paypal, Alipay

4. Currency of payment: USD / RMB

Packaging details | Standard export packing, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety; |

Shipping methods | 1.Shipping by sea(recommend big product or a lot of goods of the order) |

2.By air | |

3.By express: EMS, DHL, Fedex, UPS etc |

Liaocheng Jingwei Laser Equipment Co., Ltd., based in Liaocheng, Shandong, China, was founded in 2013. Over the years, it has evolved into a professional factory integrating R&D, manufacturing, sales, and service. The company specializes in laser engraving & cutting machines, desktop laser stamp engraving machines, fiber laser marking machines, related parts, and WD series machines. Jingwei Laser provides high-quality OEM services to overseas distributors and agents. Contact us to discuss business opportunities.

Liaocheng Jingwei Laser Equipment Co., Ltd., based in Liaocheng, Shandong, China, was founded in 2013. Over the years, it has evolved into a professional factory integrating R&D, manufacturing, sales, and service. The company specializes in laser engraving & cutting machines, desktop laser stamp engraving machines, fiber laser marking machines, related parts, and WD series machines. Jingwei Laser provides high-quality OEM services to overseas distributors and agents. Contact us to discuss business opportunities.

content is empty!